Behind the Scenes of Recycling

Ever wonder what happens after you drop an empty water bottle in your recycling bin? In this article, we walk you through the recycling process from collection to the production of new products.Byline: BTB Author

October 13, 2025 / Time to read: 3 minutesEver wonder what happens after you drop an empty water bottle in your recycling bin? It’s a common question considering the journey of recycled materials is largely invisible — and often misunderstood.

To clear things up, we’re going to walk you through the lifecycle of recyclables and show how

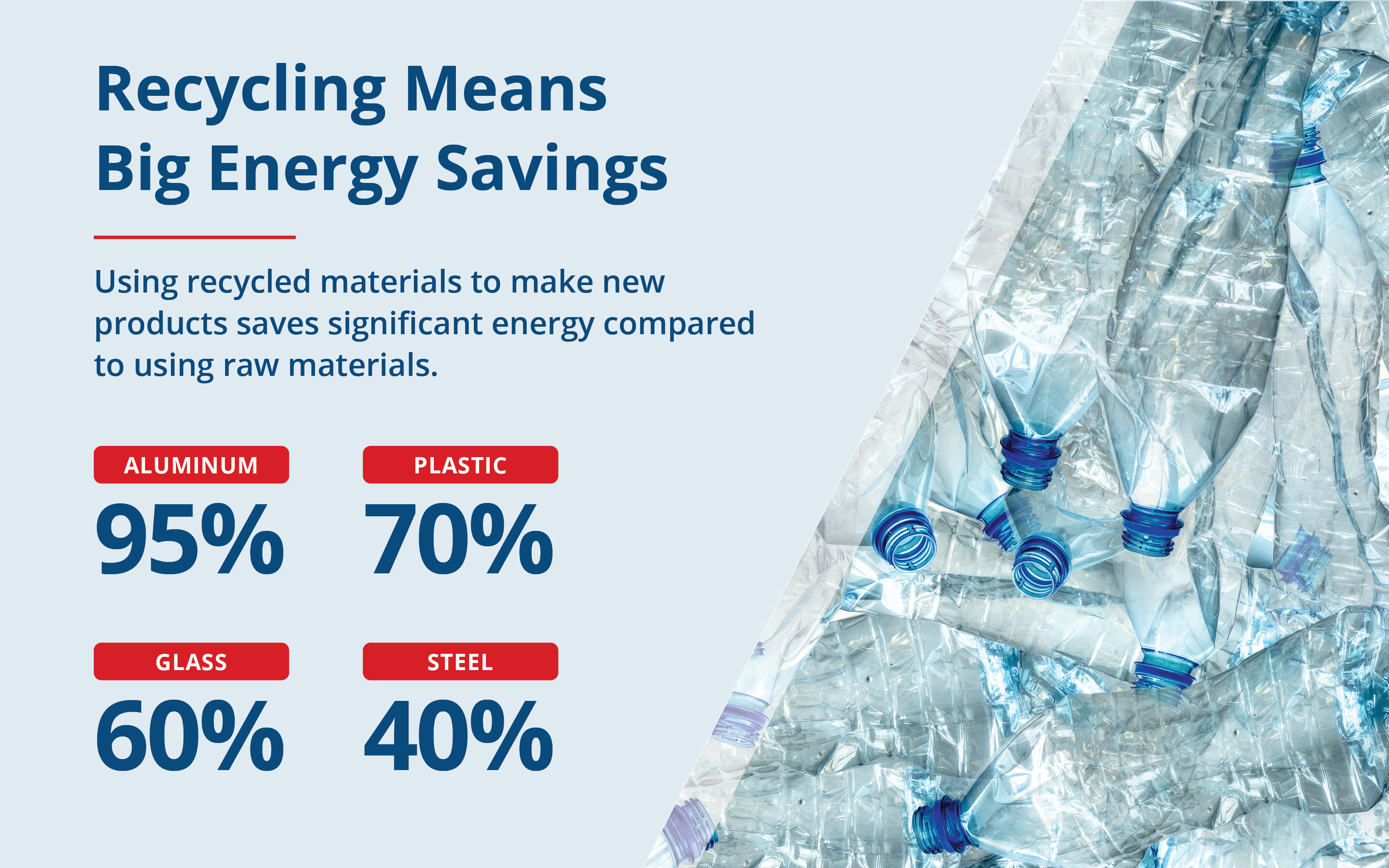

The Benefits of Recycling

Recycling delivers big

Recycling can even lower costs by helping manufacturers conserve limited resources and reduce the need for landfill space, which cuts down on production and waste disposal expenses that often get passed on to consumers.

What Really Happens to Recyclables?

Remember the water bottle we mentioned earlier? Once you place it in your recycling bin at home — empty, clean and dry, of course — it embarks on a multi-step journey before it becomes something new. Here’s what typically happens:

Collection & Sorting

When recycling begins at home, it starts by collecting recyclables and ensuring all items are free from contaminants, like leftover food or liquids. Recycling the right materials and making sure they’re empty, clean and dry are the most effective ways to make sure recyclables are actually able to be recycled.

Next, recyclables are collected and taken to recycling facilities. At these facilities, materials are sorted both manually and with automated equipment. At our own facilities, we use

- Optical sorters with vision recognition, which enabled our Southern Nevada Recycling Center to

increase aluminum recovery by 27% . - Robotic sorting arms, which we added to six recycling centers in 2024 to boost speed and accuracy.

- Ballistic separators, which significantly increase productivity and recovery rates by separating paper and cardboard from bottles and cans.

Processing

After recyclables are sorted and baled, they’re delivered to manufacturers where they’re processed by type — since different materials require different equipment and handling techniques. In the case of paper, any ink is removed from the fibers to create clean pulp for new paper products. And after plastic is cleaned, it’s shredded and turned into pellets. Throughout processing, facilities implement several quality control measures including metal detection and removal, label and adhesive removal and contamination control (like checking for food waste in paper).

Manufacturing New Products

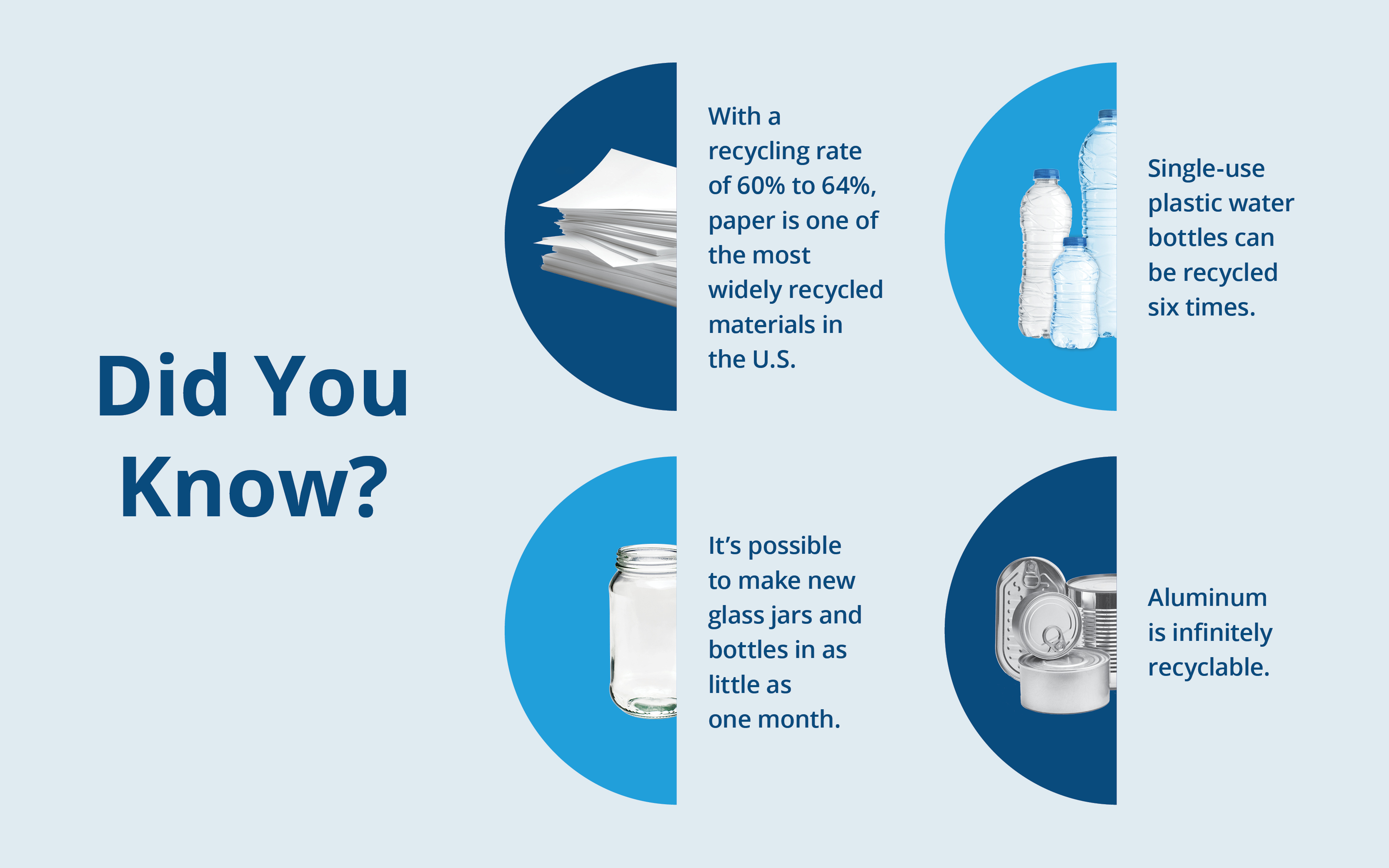

Recycling isn’t just about reducing waste. It’s also about giving new life to discarded materials. The transformation from used items to processed materials — like plastic pellets, metal sheets or glass cullet (small pieces of glass) — and then on to new products is a remarkable feat.

Here at Republic Services, we champion closed-loop recycling, meaning recycled materials are used to make the same or similar materials. Thanks to our first-of-its kind

Curious about the fate of the aforementioned recycled water bottle? Over the course of just a few weeks, it can go from your recycling bin to a store shelf as a new water bottle.

The Future of Recycling Is Bright

Republic Services operates

We understand that recycling can be a little confusing sometimes. We also know that when our customers get a glimpse inside the recycling lifecycle, they see their efforts contribute to something bigger.